what to calculate static pressure on exhaust duct

Static force per unit area creates resistance against air move in the ducts of an HVAC system, and air handling units must overcome this pressure to provide heating and cooling. The static pressure and airflow are the 2 principal factors that determine how a fan operates, and also its ability consumption. For these reasons, static pressure calculation is a very important footstep in the HVAC design procedure.

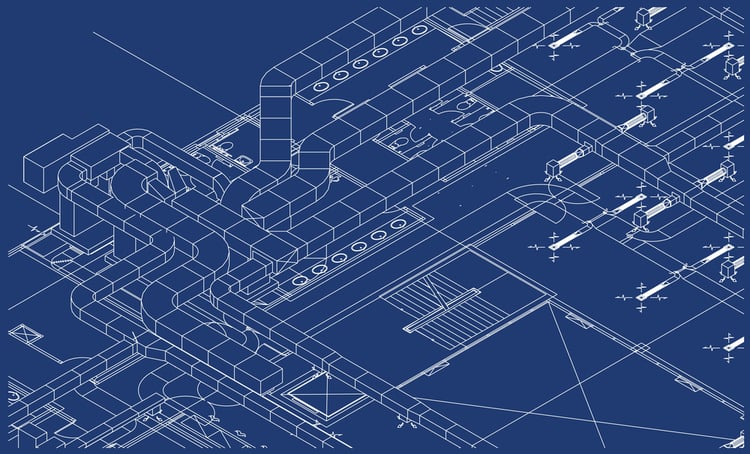

Air ducts are used in many types of HVAC systems, and their blueprint has an touch on on temperature control and energy efficiency. For example, packaged rooftop units (RTU) and fan ringlet units (FCU) are usually connected to an air duct organisation. To specify these components correctly, and accurate static pressure calculation is necessary.

Get a professional static pressure calculation and improve your building'southward HVAC design.

Fifty-fifty if you have the best air workout and space heating equipment in the market, a deficient air duct pattern can have a negative impact on their functioning. The ventilation systems must overcome static force per unit area, while minimizing dissonance and vibration. However, the static pressure can also exist reduced with smart decisions while designing the air ducts.

Air Duct Blueprint: A Cursory Overview

Before designing air ducts, HVAC engineers must summate heat load and airflow according to ASHRAE standards. They must besides find optimal locations for diffusers, air handling units and HVAC equipment. Finally, the air duct layout can be designed according to the space available.

During the ductwork design process, it is very important to avoid clashes with other building systems, such as electrical and plumbing installations. Nevertheless, BIM software can detect these problems automatically, and engineers can right them earlier construction.

The post-obit are some useful guidelines from HVAC experts when designing air ducts:

- Reduce the pressure loss in air ducts as much as possible. This besides reduces the fan horsepower required, improving energy efficiency.

- Avoid sudden changes in management when designing the air duct layout, and provide turning vanes to minimize pressure drop.

- Minimize racket and vibration, since they cause discomfort and distraction for occupants. Vibration also shortens the service life of equipment, leading to expensive repairs.

- Focus on cost-effective design: Save space and materials whenever possible, without affecting HVAC performance.

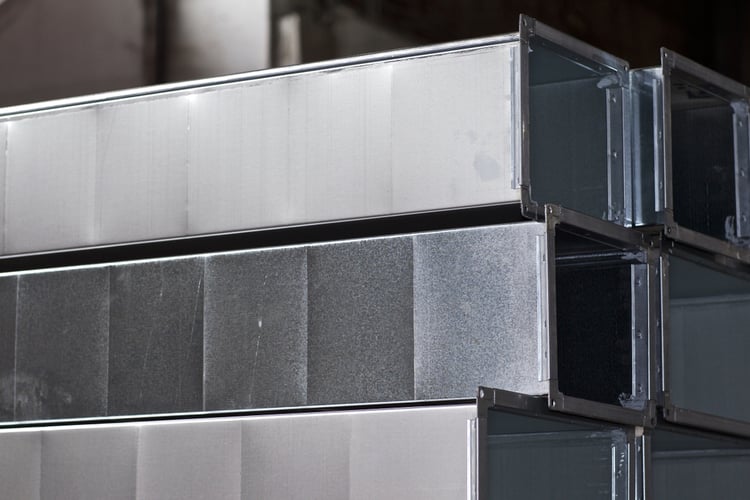

- Design air ducts with an aspect ratio as close to ane every bit possible, and no college than four.

There are iii types of air duct systems, classified based on their static pressure:

- Low-pressure systems, with a static pressure upwards to two in. w.one thousand.

- Medium-pressure level systems, with a static pressure level from 2 to 6 in. w.g.

- High-pressure level systems, with a static pressure over half dozen in. west.thousand.

A college static pressure causes more noise and vibration. Ideally, an air duct system must exist designed with the lowest static pressure that is technically feasible.

The Equal Friction Design Method

Three main methods are used to blueprint air duct systems:

- Static regain method

- Velocity method

- Equal friction method

The equal friction method is the most common in the manufacture by far, since it uses elementary calculations that consume less time. The other two methods are rarely used in modern HVAC designs.

With the equal friction method, air ducts are designed to accept a constant pressure drop per unit of length , according to the ASHRAE Fundamentals Handbook. The friction loss of the duct system is described by the average pressure level drop per 100 anxiety of ductwork.

The ASHRAE Handbook allows some design flexibility, providing charts with suggested ranges of air velocity and friction rate. Like with any engineering determination, the optimal friction and velocity depend on project conditions:

- A low friction rate consumes less fan ability, but it requires larger ducts. This design approach is recommended when electricity is expensive and ductwork is affordable.

- A high friction rate consumes more fan power, while saving on duct materials. This selection is recommended when ductwork is expensive and electricity is affordable.

All ducts are sized initially, and pressure level loss is then calculated individually for all sections. Based on the results, air ducts are resized to balance losses.

How Are Friction Losses Classified?

When designing air ducts, friction losses are classified by source - losses caused by the ducts themselves, and losses caused past fittings.

- Duct losses depend on air velocity and duct characteristics - dimensions, length and cloth roughness. An important step of the design process is identifying the critical path, which is the duct path with the highest pressure loss.

- Fitting losses account for the highest fraction of total losses. They happen when air moves through filters, offsets, elbows, dampers, coils, and other fittings and accessories. Using the right fittings in the right locations can atomic number 82 to significant cost reductions and free energy savings. ASHRAE provides fitting loss coefficients to simplify their choice.

When all the losses have been accounted for, HVAC engineers can select a fan that volition deliver the required airflow and pressure.

Final Recommendations

HVAC design is very important in edifice projects, since information technology has an touch on operation costs and maintenance expenses in the long run. HVAC too represents the highest free energy expense for most residential and commercial buildings, and smart design decisions can reduce power and gas bills. To achieve college performance, a ventilation organisation can exist equipped with occupancy sensors, and variable-frequency drives (VFD) for fan speed control.

A well designed HVAC organization also improves occupant comfort, boosting productivity in business concern settings. HVAC noise can exist reduced by selecting optimal duct sizes, after an accurate static pressure adding.

Source: https://www.ny-engineers.com/blog/static-pressure-calculation-in-hvac-design

0 Response to "what to calculate static pressure on exhaust duct"

Post a Comment